Steel Power Transmission Pole

Product Introduction

We specialize in manufacturing high-quality power transmission poles, with over 15 years of experience serving markets across Europe, the Americas, and beyond. Our poles are engineered to meet strict international standards (ANSI, EN, etc.), combining durability, environmental adaptability, and cost-effectiveness.

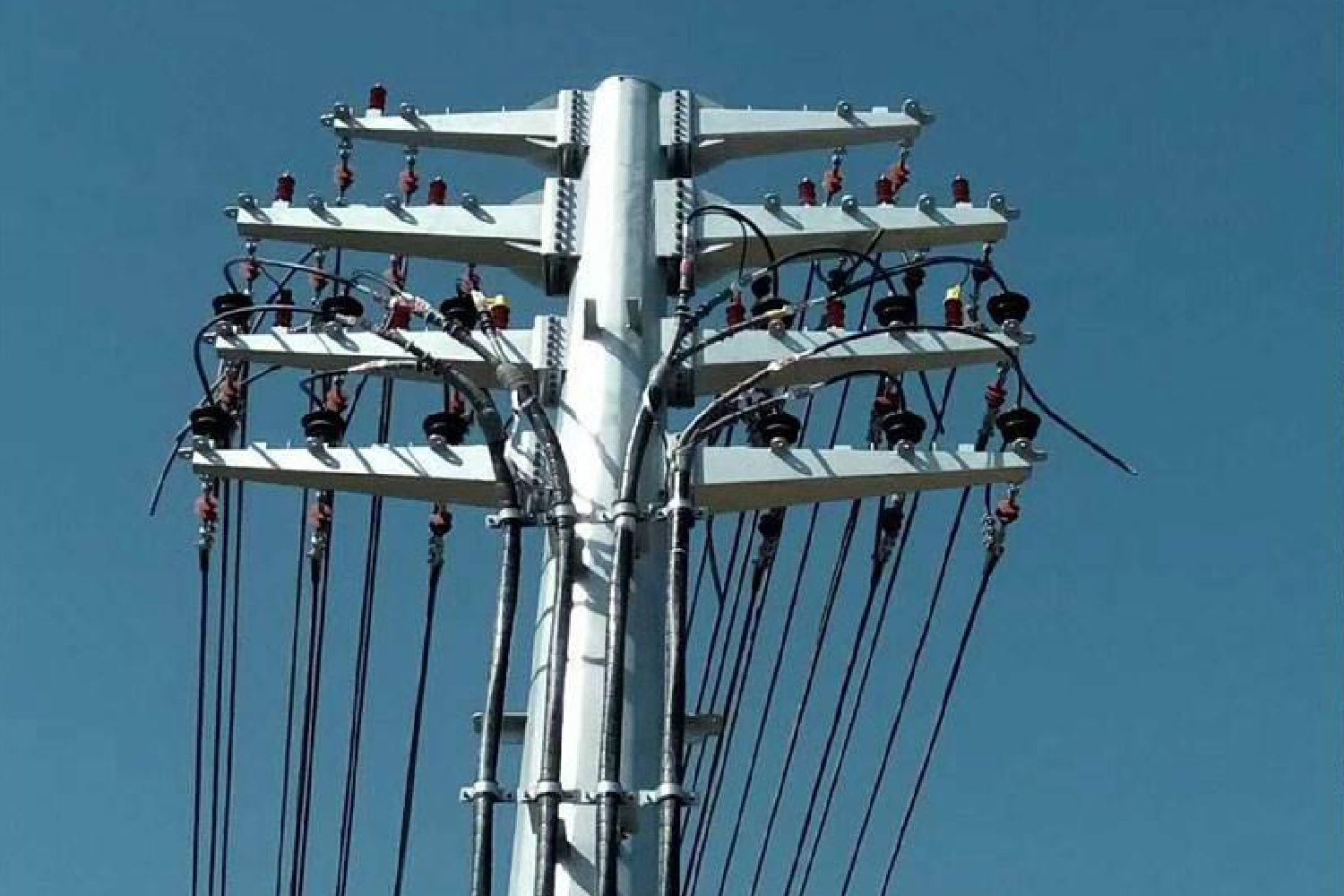

Whether for urban grid upgrades, rural power expansion, or renewable energy (wind/solar) transmission lines, our poles deliver reliable performance in extreme weather—from heavy storms to high temperatures. We aim to be your long-term partner for safe, efficient power infrastructure solutions.

Product Parameter

Product Features

Extreme Weather Resistance: High-strength materials withstand storms, snow, and UV radiation, ensuring stability in harsh environments.

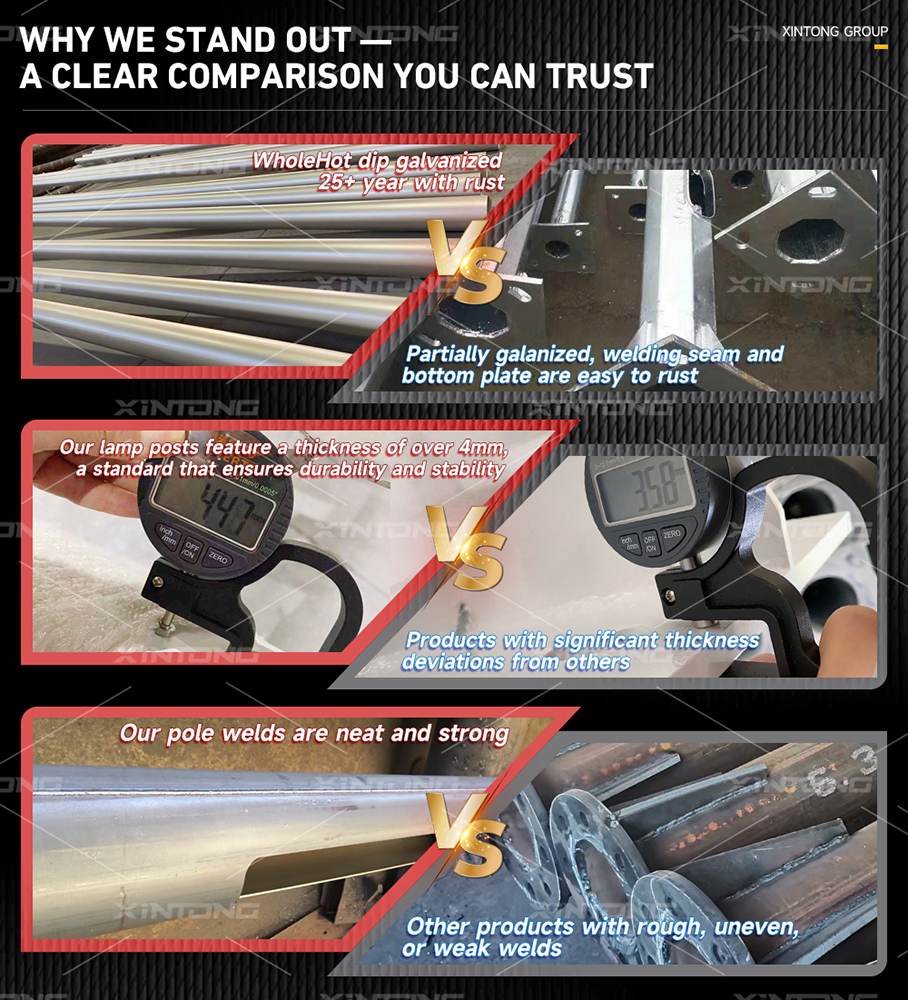

Longevity: Anti-corrosion treatment (hot-dip galvanizing) and durable materials extend service life by 30% vs. conventional poles.

Efficient Installation: Modular design with pre-assembled components reduces on-site construction time by 40%.

Eco-friendly: Recyclable materials and low-carbon production process meet EU/US environmental regulations.

Application Scenario

Urban power grid renovation (e.g., city center, suburban areas)

Rural electrification projects (remote villages, agricultural zones)

Industrial parks (high-voltage power supply for factories)

Product Detail

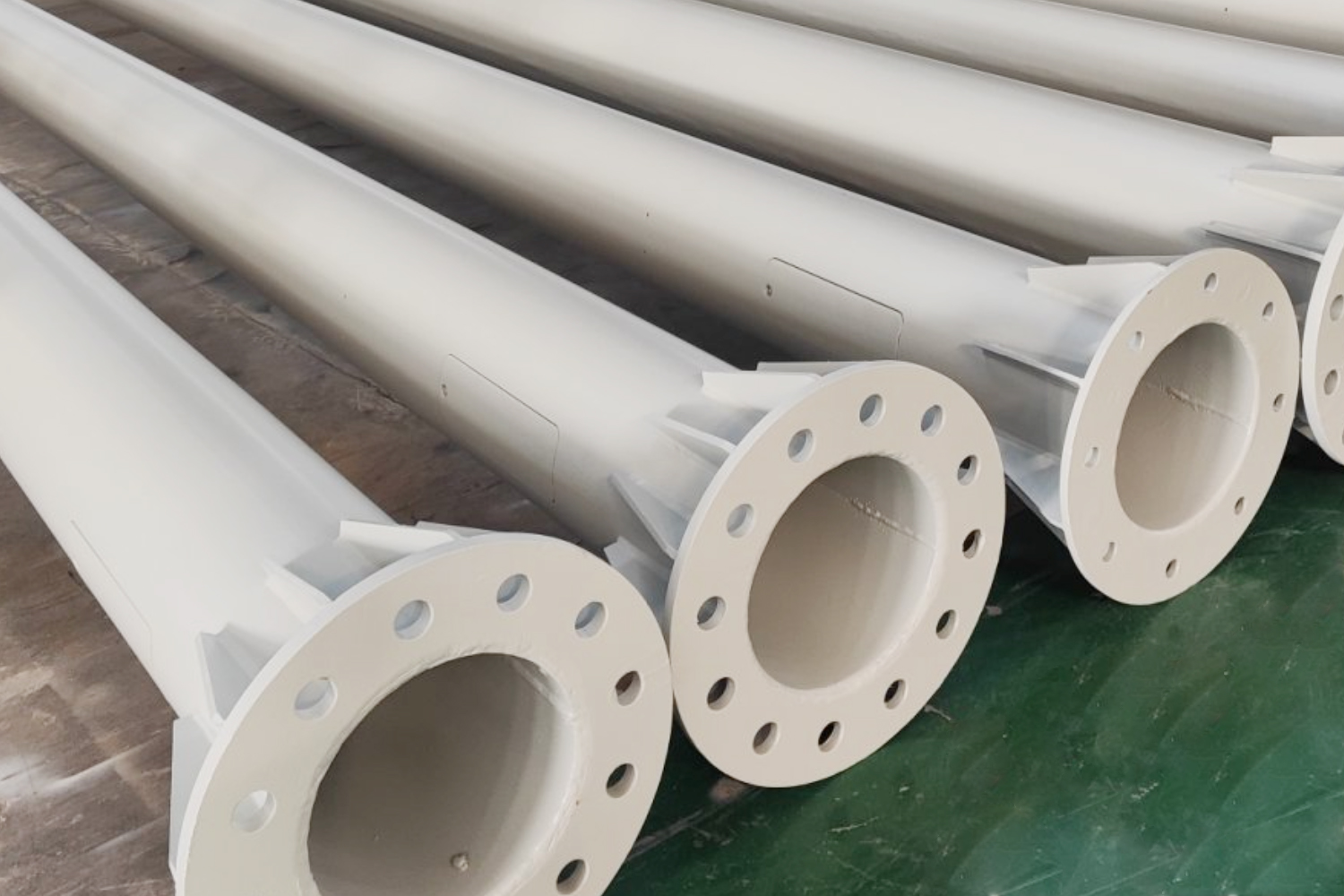

Connection Structure: Precision-machined flange connections (tolerance ≤0.5mm) ensure tight, shake-proof assembly.

Surface Protection: 85μm+ hot-dip galvanizing layer (tested via salt spray for 1000+ hours) prevents rust in coastal/humid areas.

Base Fixing: Reinforced concrete foundation brackets (with anti-slip design) enhance stability in soft soil.

Top Fittings: Customizable hardware (insulator mounts, cable clamps) compatible with global line standards.

Product Qualification

We adhere to strict quality control throughout production, supported by:

Why Choose Us ?